V engine

Something about the V Engines Design

Raffaella Aversa, Relly Victoria Petrescu, Antonio Apicella, Florian Ion Tiberiu Petrescu, John Kaiser Calautit, MirMilad Mirsayar, Ronald B. Bucinell, Filippo Berto and Bilal Akash

DOI : 10.3844/ajassp.2017.34.52

American Journal of Applied Sciences

Volume 14, Issue 1

Pages 34-52

Abstract

First time the corresponding author has studied these problems of motors in V, in the framework of some contracts made with the research collective of UPB and "Autobuzul" plant, in years 1980-1986. In the first phase, have been studied the vibrations and noises of an engine in V, their transmissibility from the engine to the chassis and the cab driver and the possibility of reducing vibration (of the engine or the submitted) by their insulation. Reducing the vibration transmitted, has taken place in various ways, but their level at the driver's seat and the passengers was still too large, much more than the allowed limits international. The vibrations were still more than the allowed limits, while in a similar engine Otto or diesel in a straight line, they were in line with the normal limits, until at last it was decided to change the type of the engine. The idea of the paper's authors was: "It can be synthesized one motor in V only by changing the alpha angle value (the constructive angle of a V engine)". By this method it is possible to change the kinematics of this motor and in the same time its dynamic work. Generally the constructive angle of an engine in V was calculated in function of the number of cylinders and by the engineering condition to achieve an ignition distributed uniformly to all cylinders. This paper try to solve the principal problem of any motor in V (noise and vibration) having in view that one motor in V is more dynamic, more powerful and has a higher yield than any other heat engine. The solution was found and it is very simple to be implemented. It needs only an angle value change. It's about the constructive angle, alpha. Calculations to demonstrate this fact and all the theory are very difficult and heavy. But the final result is very simple.

Copyright

© 2017 Raffaella Aversa, Relly Victoria Petrescu, Antonio Apicella, Florian Ion Tiberiu Petrescu, John Kaiser Calautit, MirMilad Mirsayar, Ronald B. Bucinell, Filippo Berto and Bilal Akash. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

From Wikipedia, the free encyclopedia

| This article needs additional citations for verification. (September 2013) (Learn how and when to remove this template message) |

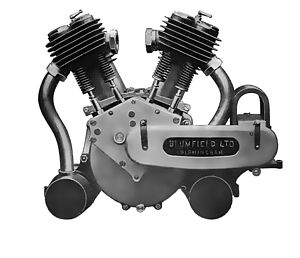

An early Vee engine - this is a two-cylinder V-twin used in an early British motorcycle

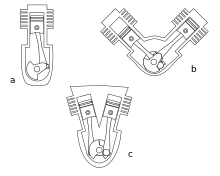

Three types of engine: a — straight engine, b — Vee engine, c — VR6 engine

The yellow lines indicate the 'angle' of the 'Vee'

Contents

History

The first V-type engine, a 2-cylinder vee twin, was built in 1889 by Daimler, to a design by Wilhelm Maybach. By 1903 V8 engines were being produced for motor boat racing by the Société Antoinette to designs by Léon Levavasseur, building on experience gained with in-line four-cylinder engines. In 1904, the Putney Motor Works completed a new V12 marine racing engine – the first V12 engine produced for any purpose.[1]Characteristics

Usually, each pair of corresponding pistons from each bank of cylinders share one crank pin on the crankshaft, either by master/slave rods or by two ordinary connecting rods side by side. However, some V-twin engine designs have two-pin cranks, while other V configurations include split crank-pins for more even firing.V-engines are generally more compact than straight engines with cylinders of the same dimensions and number. This effect increases with the number of cylinders in the engine; there might be no noticeable difference in overall size between V-twin and straight-twin engines while V8 engines are much more compact than straight-eight engines.[2]

Various cylinder bank angles of Vee are used in different engines; depending on the number of cylinders, there may be angles that work better than others for stability. Very narrow angles of Vee combine some of the advantages of the Vee engine and the straight engine (primarily in the form of compactness) as well as disadvantages; the concept is an old one pioneered by Lancia's V4 engine in the 1920s, but recently reworked by Volkswagen Group with their VR engines, which is actually a combination of V and straight configuration.

Some Vee configurations are well-balanced and smooth, while others are less smoothly running than their equivalent straight counterparts.[citation needed] V8s with crossplane crankshaft can be easily balanced with the use of counterweights only. V12s, being in effect two straight-6 engines married together, are fully balanced; if the V-angle is 60° for 4-stroke or 30° for 2-stroke, they have also even firing. Others, such as the V2, V4, V6, flatplane V8, V10, V14 and V18 engine show increased vibration and generally require balance shafts or split crankshafts.

Niciun comentariu:

Trimiteți un comentariu